The Main Difference Between A Static Hydraulic Pump And A Hydraulic Pump Lies In Their Working State And Application Scenarios

Working Condition

1. Static hydraulic pump: In a static hydraulic system, the liquid is in a stable static state, and energy conversion occurs in a static state. In this state, the operating speed of hydraulic components is slow and the noise generated is extremely low.

2. Hydraulic pump: In the power hydraulic system, the liquid is in a dynamic state, the liquid flow speed is fast, and the noise generated is relatively high.

Application scenarios

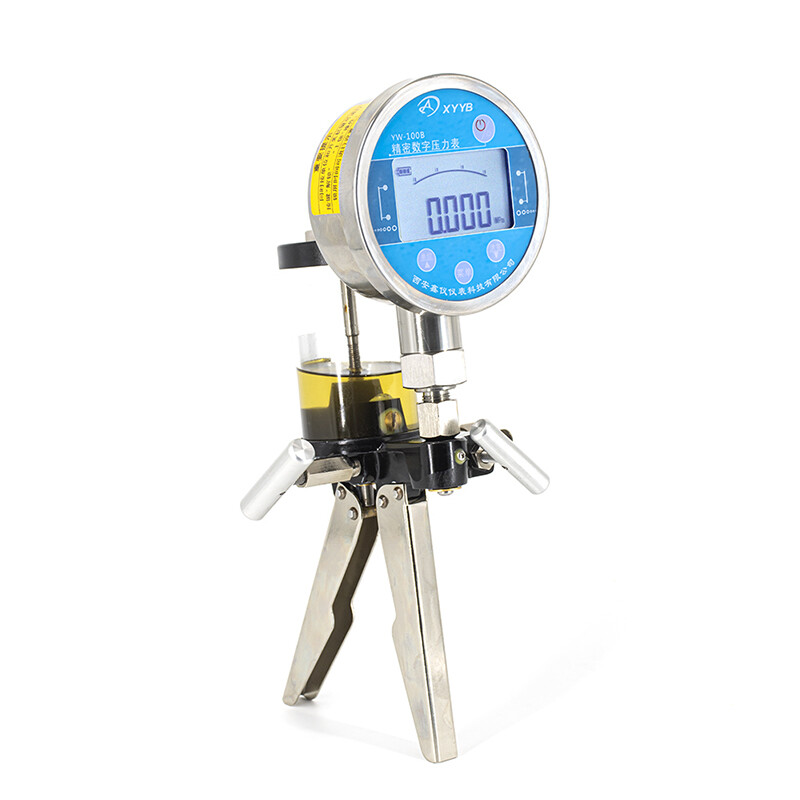

1. Hydrostatic pump: Suitable for applications that require low noise and high precision, such as precision instruments, laboratory equipment, etc. Due to its low noise and high precision, static hydraulic pumps are widely used in various fields such as metallurgy, aviation, railway, engineering machinery, and automobiles

2. Hydraulic pump: suitable for general industrial applications, such as engineering machinery, metallurgy, papermaking, petroleum and other fields. Power hydraulic pumps exhibit high efficiency and applicability in these fields

Comparison of advantages and disadvantages

Hydrostatic pump:

Advantages: Low noise, high precision, suitable for situations that require precise control.

Disadvantage: The power output is relatively low, making it suitable for situations with static or low dynamic requirements.

Advantages: High power output, suitable for high dynamic demand scenarios.

Disadvantages: High noise and relatively low accuracy

Contact

Chat Online